History of the plant

Over the years, in line with the requirements of the time, the company perfected the production technology of special grades of pulp.

Over the years, in line with the requirements of the time, the company perfected the production technology of special grades of pulp.

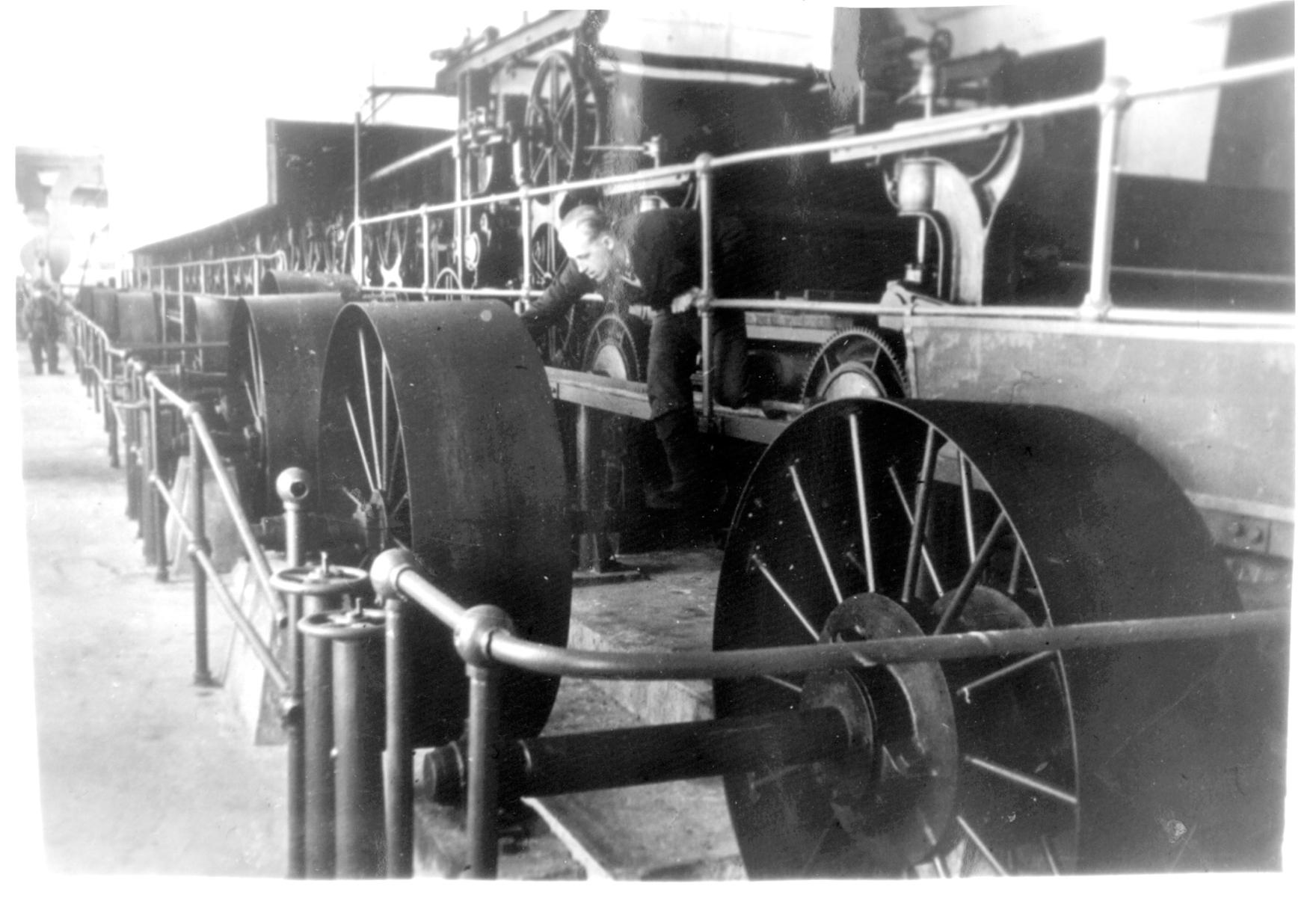

The history of the plant dates back to the days when Norwegian Dizen Christopher Ditlev in the early twentieth century, built on about. Pusunsaari sulphate pulp mill DIESEN WOOD , which was already in 1921 produced 5508 tons. At the time, was worked out 15 pulp grades, which went on sale in Finland, France, Germany, as well as the timber for England, Holland, Belgium and France.

In 1940, commodity output increased to 40 tons. The factory was partially destroyed in the 1939-1945 years, but some of the equipment evacuated.

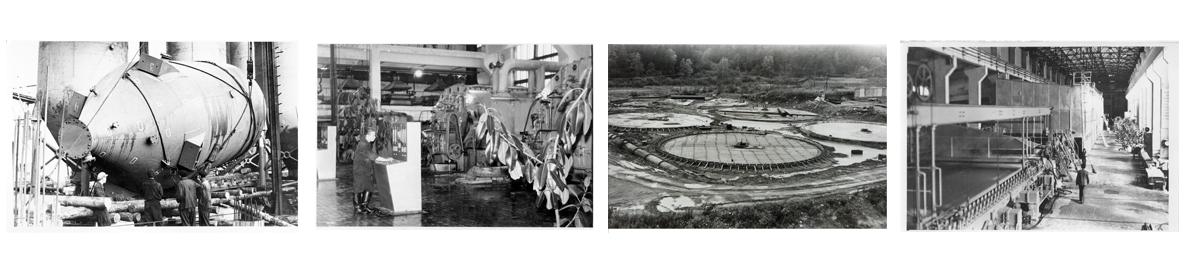

July 1, 1947 the date of the most important post-war history. Then in the restored shops, production resumed, and began production of stiff unbleached pulp, which became the basis for all brands of modern products.

Union value the company acquired in 1948, for the first time in the country has mastered the production of cellulose capacitor, and the first batch of domestic bleached kraft pulp was released in 1949.

Since 1962, the plant started another kind of semi-bleached sulphate pulp production for paper Tetra-pak. In 1970 started the production of pulp for of insulation. In 1993, to improve the competitiveness of the enterprise has mastered release of cellulose for taroupakovochnykh kinds of paper and cardboard. In 2010, mastered release of cellulose for use in the manufacture of fiber cement.

capabilities

The factory has a wealth of experience, flexible technology and highly qualified personnel. We are continuously improving our quality management system.In 2003, the company has implemented and successfully operates a quality management system according to ISO 9001: 2008.

The plant has a strong position in the market of unbleached pulp, the share of production enterprises in the world market amounts to 3.5 percent. Delivery geography covers many countries around the world, and the authority of the manufacturer's quality products and reliable partner grows. Perspective development of the plant is aimed at modernizing production in order to improve their processes, achieve consistently high product quality, increase production. The company conducts environmental activities in line with modern Russian and international requirements, pays great attention to the environmental situation in the affected area, introduces new environmental and resource-saving technologies and equipment. Special attention is paid to training of personnel and training reserve personnel for the maintenance of high professional skills of workers.

Contacts

Contacts office@pitzavod.ru

office@pitzavod.ru

Republic of Karelia, Pitkyaranta district, Pusunsaari Island, 1

Republic of Karelia, Pitkyaranta district, Pusunsaari Island, 1